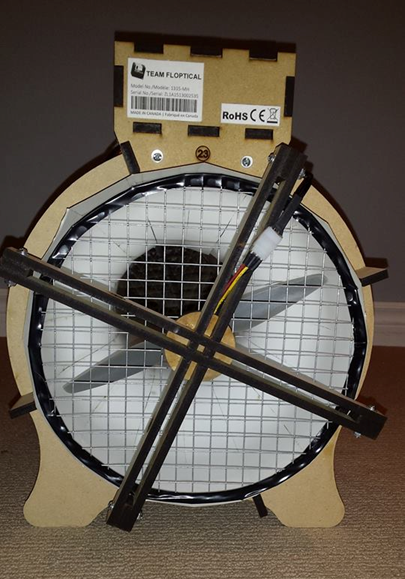

1315-MH Wind Tunnel

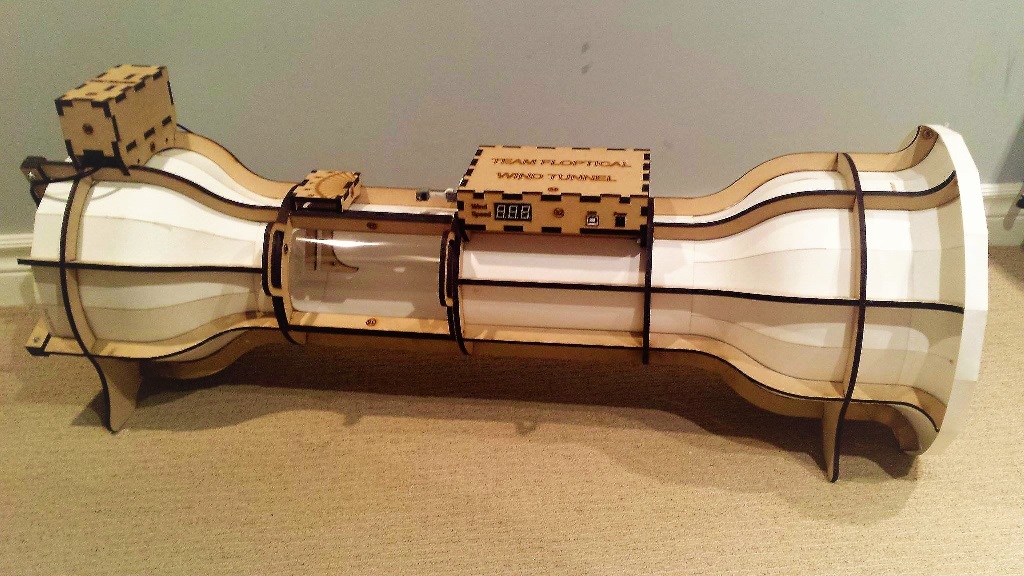

This project emerged as a solution to a challenge - building a wind tunnel capable of measuring the forces of lift and drag on an airfoil and the speed of the air in the chamber.

Before beginning the prototyping process, teams were required to provide a complete report describing proposed designs for the project, equipment, and the research and theory that showed the design could be successful.

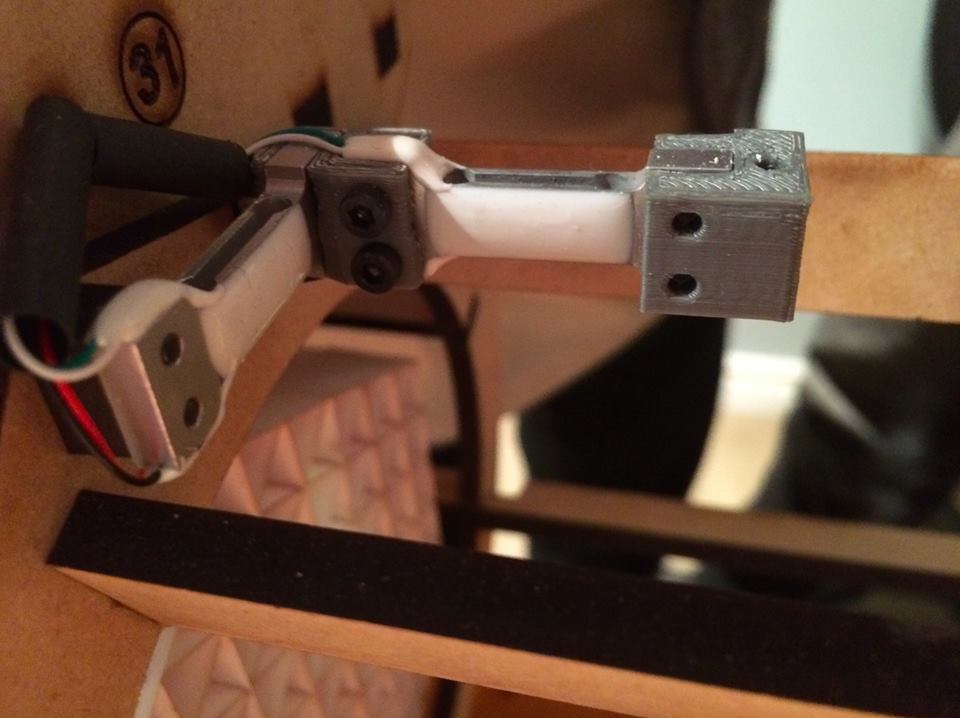

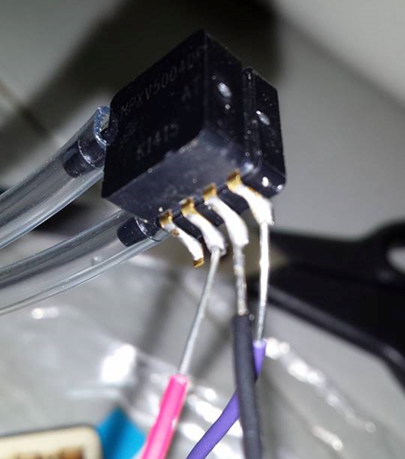

Upon completing the research, micro load cells with amplifiers were selected to measure lift and drag, a brushless DC motor from a RC aircraft to power the fan, a 7-segment display to show windspeed or loads, a differential pressure gauge to measure windspeed, and an Arduino Mega to control input from all the sensors.

The load cells (left) were selected to be able to measure forces on the scale of millinewtons. The differential pressure gauge (right) measured the difference in pressure between each tube. One tube would be placed into the wind, and the other perpendicular to the flow. Thus, the reading could then be converted to a wind speed using Bernoulli's principle.

The final product was a structure laser cut from MDF and construction paper, with ports to accomodate the sensors, the battery for the fan, and the Arduino. The acrylic access hatch allowed easy visiblity into the tunnel and allowed airfoils to be placed inside easily. Overall, the wind tunnel worked as expected and read forces accurately.

Design Report: Design and Force Analysis of a Wind Tunnel